ศตวรรษแห่งความแข็ง: ประวัติความเป็นมาของทังสเตนคาร์ไบด์

ข่าวอุตสาหกรรม-From Lightbulbs to Rock Drills: The Discovery

The story of tungsten carbide (WC) is one of industrial necessity driving a breakthrough in materials science.

The Element Tungsten

The journey begins in the 18th century with the discovery of the element Tungsten (W) . Known for its incredible density and the highest melting point of all metals (over $3,400^{\circ}\text{C}$), it quickly became the material of choice for filaments in incandescent lightbulbs in the early 1900s. The process of drawing this incredibly tough metal into fine wires required dies that were nearly as hard as diamond.

The Birth of Cemented Carbide

The crucial breakthrough occurred in Germany in the 1920s . Engineers at the electric bulb company Osram were desperately seeking a cheaper, tougher alternative to the expensive diamond dies used to draw tungsten wire. This need led to the invention of cemented carbide (or hardmetal) by Karl Schröter.

- The Idea: Combine the extreme hardness of tungsten carbide (WC) powder with a ductile, metallic “glue”— cobalt .

- The Result: The first modern hardmetal: a composite material with the scratch resistance of ceramic but the toughness and impact resistance of metal. This revolutionary material quickly replaced diamond in drawing dies and soon spread to the wider world of cutting and drilling.

The Science of Strength: Why WC is So Hard

What gives tungsten carbide its diamond-like hardness? The answer lies in the atomic-level bonding between the tungsten and carbon atoms.

The Crystal Structure

Tungsten carbide forms a unique crystal lattice. In the compound (WC), the carbon atoms fit into the spaces between the much larger tungsten atoms. The resulting structure features extremely strong covalent bonds between the tungsten and carbon, combined with strong metallic bonds between the tungsten atoms themselves.

This combination is what creates the famous properties:

- Extreme Hardness: The strong, directional covalent bonds resist deformation and scratching. It typically scores 9 to 9.5 on the Mohs scale , second only to diamond (10).

- High Strength and Toughness: The metallic cobalt binder that holds the WC particles together provides the necessary toughness —a resistance to breaking or shattering under impact—which pure, brittle tungsten carbide powder would lack.

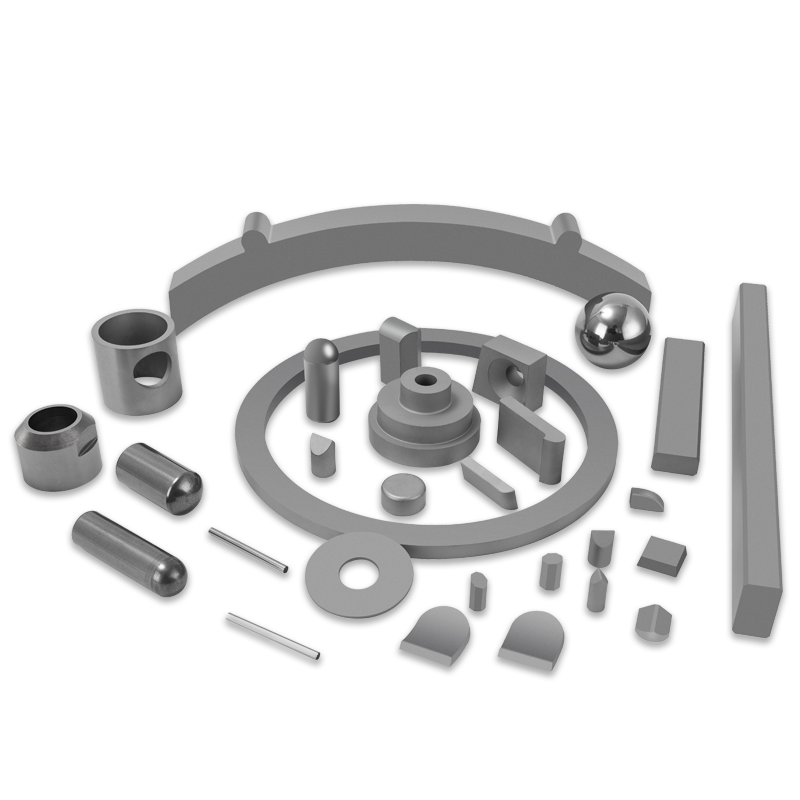

The fine particles of tungsten carbide are dispersed throughout the cobalt matrix, creating a metal matrix composite that is far superior to any single material for heavy-duty applications.

Tungsten Carbide in the Modern World: Industrial Transformation

The widespread adoption of cemented carbide led to an industrial revolution, boosting productivity across nearly every heavy industry.

Efficiency in Machining

Tungsten carbide tools can maintain a sharp edge at temperatures that would cause a traditional steel tool to quickly dull (a property called hot hardness ).

- Impact: This allows manufacturers to increase cutting speeds and feed rates on lathes and milling machines up to five times faster than with high-speed steel (HSS) tools, drastically reducing production time and costs.

Domination in Mining

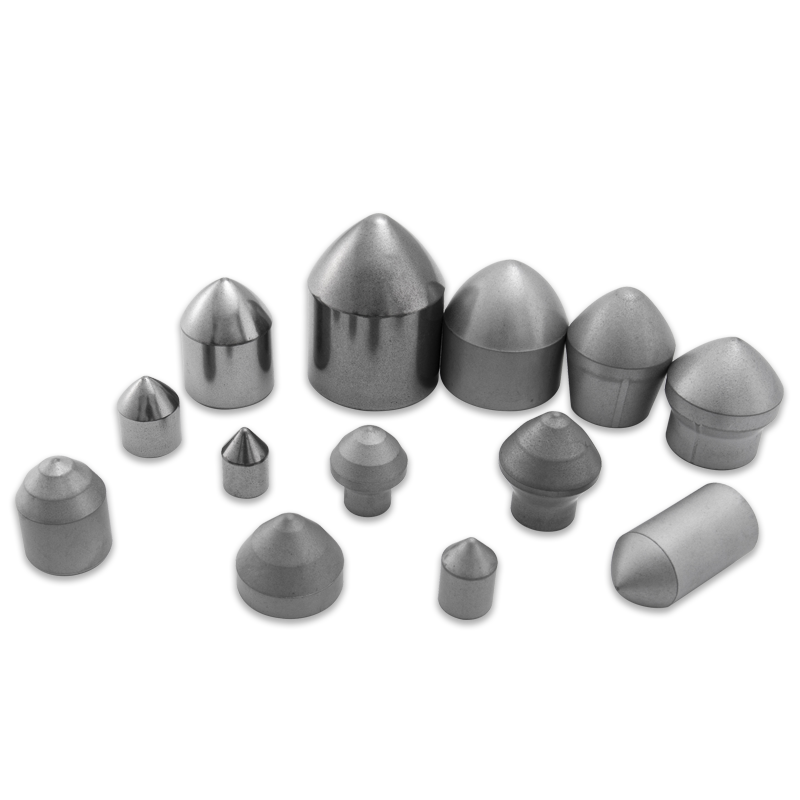

In the resource sector, tungsten carbide tips are literally chewing through the planet’s toughest materials.

- Rock Drilling: Bits used for oil and gas exploration, as well as rock breaking, are studded with WC inserts. These bits can last 10 times longer than steel tools, reducing costly downtime for maintenance.

- Construction: Tunnel boring machines (TBMs) rely on tungsten carbide-tipped discs to grind through mountains and lay new subway tunnels or infrastructure.

The Toughest Competition: WC vs. Titanium

While often confused, tungsten carbide and titanium serve very different purposes due to their core properties.

| Property | Tungsten Carbide (WC) | Titanium (Ti) |

|---|---|---|

| Primary Advantage | Extreme Hardness & Scratch Resistance | High Strength-to-Weight Ratio & Corrosion Resistance |

| Density/Weight | Very High (Heavy, similar to Gold) | Low (Light, similar to Aluminum) |

| Mohs Hardness | 9 - 9.5 (Extremely Hard) | ~6 (Moderate Hardness) |

| Impact Resistance | Brittle (Can shatter on extreme impact) | Tough (Resistant to cracking/shattering) |

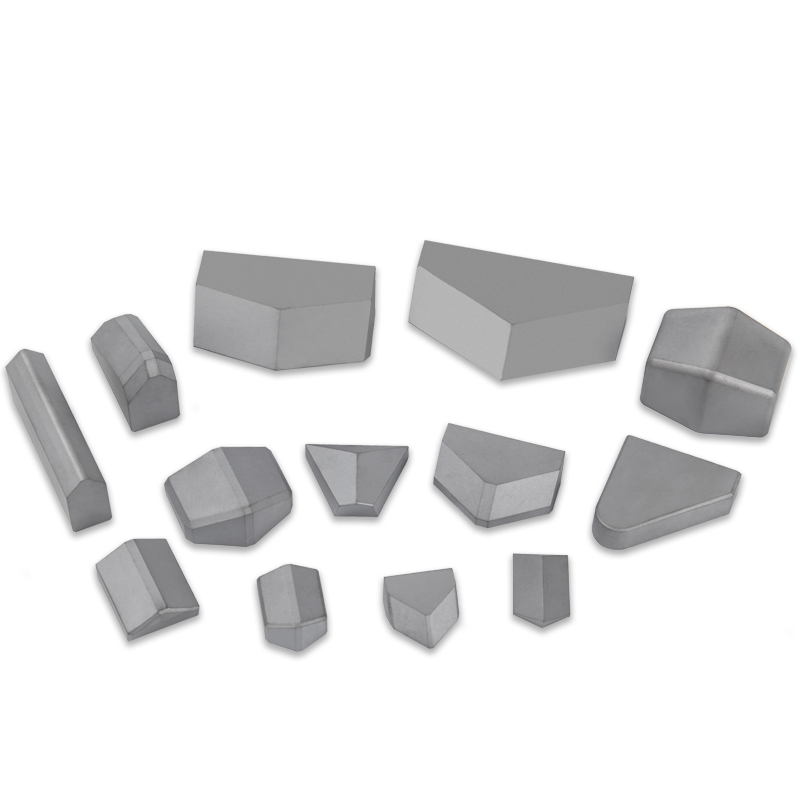

| Common Uses | Cutting Tools, Mining Drills, Wear Parts, Scratch-Proof Rings | Aerospace Components, Medical Implants, High-End Sports Gear |

In short, if you need a lightweight, impact-resistant material (like for an aircraft wing or a body implant), you choose Titanium . If you need the hardest, most abrasion-resistant material to cut or grind something, you choose Tungsten Carbide .